2022 Become distributor GE Silicone ( General Electric )

2022 Become distributor GE Silicone ( General Electric )

Structural Silicone Glazing:

Redefining Boundaries to Achieve the “Impossible”

More than 70 years ago, GE ingenuity fueled the discovery of silicone. In the decades that

followed, GE laboratories inspired innovations to silicone that created items such as gasket

seals for WWII bombers and the protective shields for the boots and space suits worn by

Neil Armstrong and his fellow astronauts. Building on the advancements from WWII and the

U.S. Space Program, GE scientists continued to move forward, honing new applications for

silicone that would serve as proving ground to silicone’s indispensable use in modern day

construction.

Today, the sealants team is at the forefront of the construction industry in the manufacturing and application

of products used in structural silicone glazing (SSG), a cutting-edge construction method. GE scientists and

lab engineers helped to pioneer SSG in the 1970s which, over time, transformed the world’s skylines into

towering skyscrapers and mirrored marvels. From the daring construction of the Chicago Art Institute in

1974, the world’s first four-sided structural silicone glazing project without safety mechanisms, to the recent

completion of the Shanghai World Financial Center, the world’s tallest completed two-sided SSG façade, the

sealants team of experts is behind many of the world’s most awe-inspiring structures.

Outstanding mechanical properties, coupled with excellent flexibility across a wide temperature range

and lasting durability, are fundamental to the high performance of GE sealants. This combination makes it

possible to respond to today’s ever-more-inventive, increasingly demanding architectural designs. Simply put,

GE structural silicone glazing solutions help make the impossible possible

Structural Silicone Glazing:

Redefining Boundaries to Achieve the “Impossible”

More than 70 years ago, GE ingenuity fueled the discovery of silicone. In the decades that

followed, GE laboratories inspired innovations to silicone that created items such as gasket

seals for WWII bombers and the protective shields for the boots and space suits worn by

Neil Armstrong and his fellow astronauts. Building on the advancements from WWII and the

U.S. Space Program, GE scientists continued to move forward, honing new applications for

silicone that would serve as proving ground to silicone’s indispensable use in modern day

construction.

Today, the sealants team is at the forefront of the construction industry in the manufacturing and application

of products used in structural silicone glazing (SSG), a cutting-edge construction method. GE scientists and

lab engineers helped to pioneer SSG in the 1970s which, over time, transformed the world’s skylines into

towering skyscrapers and mirrored marvels. From the daring construction of the Chicago Art Institute in

1974, the world’s first four-sided structural silicone glazing project without safety mechanisms, to the recent

completion of the Shanghai World Financial Center, the world’s tallest completed two-sided SSG façade, the

sealants team of experts is behind many of the world’s most awe-inspiring structures.

Outstanding mechanical properties, coupled with excellent flexibility across a wide temperature range

and lasting durability, are fundamental to the high performance of GE sealants. This combination makes it

possible to respond to today’s ever-more-inventive, increasingly demanding architectural designs. Simply put,

GE structural silicone glazing solutions help make the impossible possible

Others

Training Session Machine knowledge at Bosch representative office

Staff of Dung Tien Co.,LTD always enrich their knowledge to serve customers with the best way.

Training Session Products knowledge at 3M representative office

Staff of Dung Tien Co.,LTD always enrich their knowledge to serve customers with the best way.

Visiting Saint-Gobain Group in Vietnam

Staff of Dung Tien Co.,LTD always enrich their knowledge to serve customers with the best way.

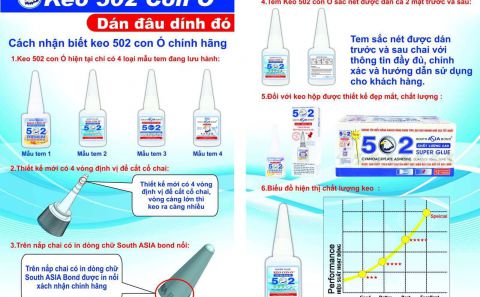

How to recognize the real Super glue 502

How to recognize the real Super glue 502

Newest catalogues of Dung Tien Company

Catalogue Dũng Tiến 201